Laser prints

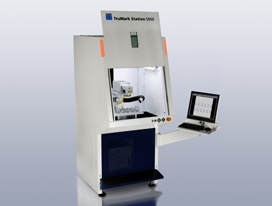

A laser marking device consisting of a robot and a laser printer. The robot stand consists of a TruMark Station 5000 R workstation with operator seating and a rotary table and a laser source, i.e. a TruMark 6330 marking laser with Nd: YVO4 crystal and 355 nm wavelength. This device allows a more effective way (i.e. cheaper, better and faster) and safer (for the environment and employees) to carry out the labeling process for products. This technology does not force the use of any chemicals that strongly affect the level of operator's occupational health and safety. It also does not require maintaining constant climatic parameters in the room due to the sensitivity of the means used for production. This technology allows for the complete elimination of chemicals from the process by burning the laser print. Other advantages also include: significantly increasing work efficiency, eliminating the need to produce one type of product per work shift, eliminating costs associated with overproduction storage, eliminating long drying times for prints, eliminating the need to dry large warehouse space elements.

Laser parameters:

- beam quality (M²) <1.6

- 355 nm wavelength

- Nd: YVO4 crystal

- laser pulse period of 7 ns at 20 kHz

- cw pulse repetition rate, 1 kHz - 120 kHz

- minimum focal distance 16 μm with 100 mm focal length

- max setting of internal focal length ± 18 mm with 260 mm focal length

- scanner accuracy calibration ± 50 μm

- max marking field size 170 mm x 290 mm with 420 mm focal length

Implementation of laser printing technology at Zamel

Regionalny Program Operacyjny Województwa Śląskiego - realna odpowiedź na realne potrzeby

Tytuł projektu: "Wdrożenie technologii wypalania nadruków laserem w firmie Zamel".

Nazwa Beneficjenta: ZAMEL Sp. z o.o.

Wartość projektu: 668.999,20 pln

Wartość dofinansowania: 274.180,00 pln

Projekt współfinansowany przez Unię Europejską z Europejskiego Funduszu Rozwoju Regionalnego w ramach Regionalnego Programu Operacyjnego Województwa Śląskiego na lata 2007 - 2013.

Informacje źródłowe na temat Regionalnego Programu Operacyjnego Województwa Śląskiego na lata 2007-2013 znajdują się na stronie internetowej www.rpo-silesia-region.pl

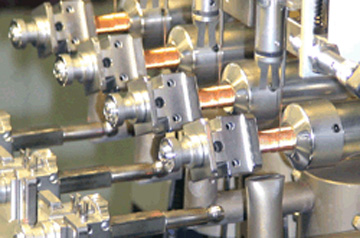

Coil winding

Basic data:

- number of spindles: 8;

- spindle spacing: 100 mm;

- max. wire diameter: 0.8 mm;

- max diameter of coils: 70 mm;

- max. length of coils: 100 mm;

- max. winding speed: 15000 rpm;

- spindle stop accuracy: ± 0.01o;

- mechanical indexing of spools;

- mechanical and electronic zero point;

- two independent analogue strain gauges for each spindle for wire diameters: 0.06 ÷ 0.24 mm and 0.20 ÷ 0.71 mm

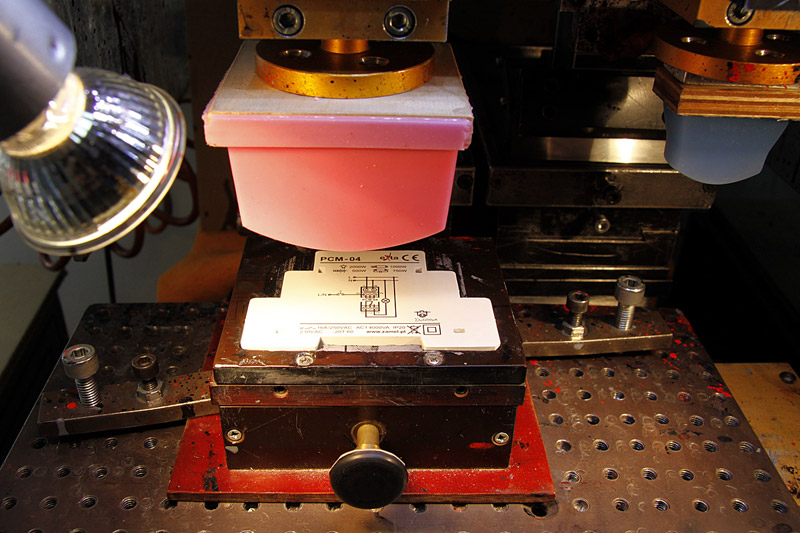

pad

The machine has the ability to set the pressure force for each color separately. The ability to configure ink assemblies (open or closed) allows you to customize the machine to individual needs.

Ink prints

We use solutions with the head moved manually or automatically, printing on stationary objects.

The devices are designed for multi-colored dye inks (ie homogeneous inks without pigment).

They enable applying durable and legible prints on various surfaces - smooth, porous, also on uneven surfaces of irregular shape such as cables, tubes, covers, bags, embossed packaging, etc.

We have the following single-head industrial printers

1. Printer EBS 6000 series - 3 pcs.

Basic data:- letter height: 1.5 ÷ 14 mm;

- distance of the head from the object: 1 ÷ 30 mm;

- head position during printing: any;

- character size (matrices): 5x5, 7x5, 9x5, 9x7, 11x8, 12x6, 12x7, 14x9, 16x10, 16x14, 21x15, 25x15, 32x18;

- number of lines: max. 4 in a matrix of 7x5 points;

- Graphics: graphics of any length and height up to max. 32 points placed at any point of the printed text;

- Bar codes: Datalogic, Matrix, 2/5 5 Bars, Interleaved, Alpha 39, EAN-8, EAN-13, Code 128, EAN-128, Code 128B, ITF8, ITF14.

2. Printer series WILLETT 460 -2 pcs.

Basic data:- letter height: 2 ÷ 10 mm;

- distance of the head from the object: optimally 9 mm;

- head position during printing: any;

- character size (matrices): 5 x 5, 7 x 5, 9 x 6, 12 x 8, 16 x 11, 19 x 14, 24 x 17;

- number of lines: max. 4 in a matrix of 7 x 5 points;

- graphics: graphics of any length and height up to max. 24 points placed at any point of the printed text;

- bar codes;

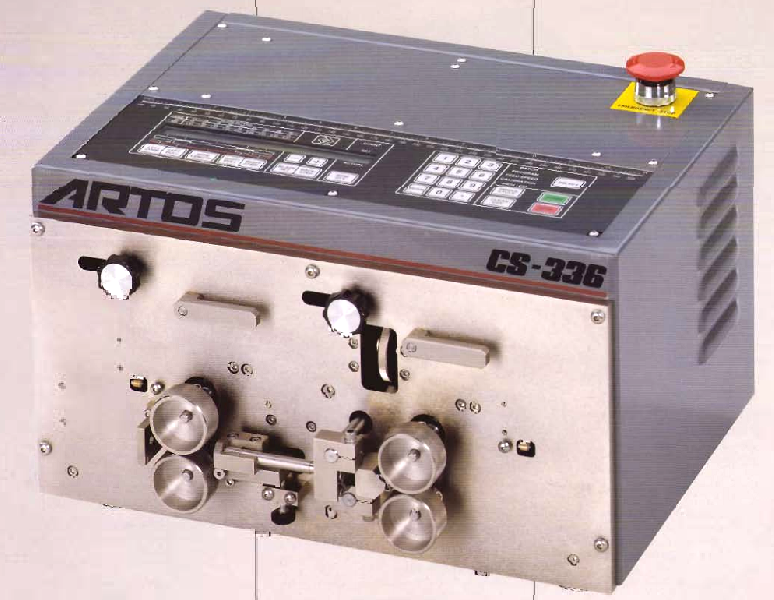

Cable harness

The full range of manufactured cables can be found at: http://zamel.pl/ CET tab. We have a fully equipped machine park for cable processing, crimping cable ends and assembly of bundles and sockets, cable plugs. We have the ability to make special tools for assembly and testing bundles with endings.

Basic data:

- wire cross sections: 30 ÷ 12 AWG / 0.25 ÷ 3 mm2;

- max cable diameter: 6.35 mm;

- stripping insulation: 0.25 ÷ 25.4 mm;

- cutting cables: 1.4 ÷ 99.99 mm;

- cutting accuracy: 0.2% of length;

Engineering department

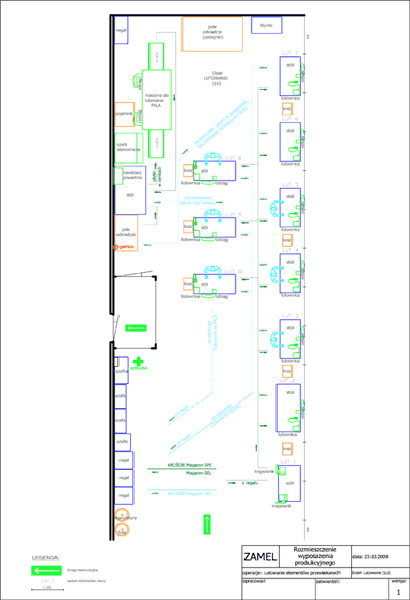

The engineering department is responsible for the proper preparation of individual assembly stations, as well as for continuous monitoring and optimization of the production process.

Well-developed technology affects the high efficiency of work at all stages of assembly. Engineers prepare production documentation, design tools, components of devices and assembly as well as control and measuring devices.

Example of a drawing with the arrangement of production equipment: