Offer

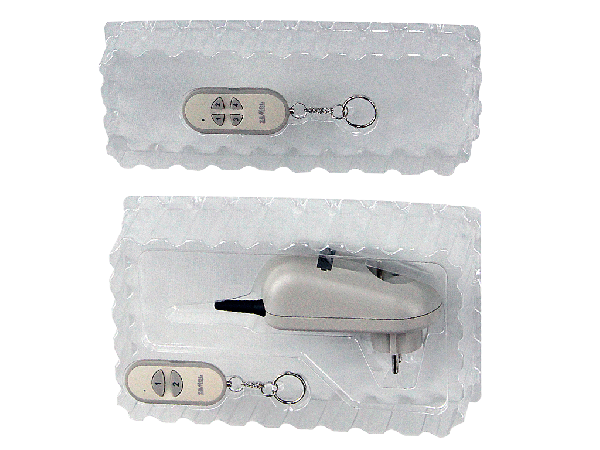

Thermoforming is a technology used to produce packaging from flat foil sheets. As a result of even heating of sheets and vacuum forming, we get durable, transparent BLISTER packaging.

We have many years of experience in designing technology preparation and implementing complex packaging projects. In our factory, we produce packaging from thermoformable films for packaging technical articles. As basic packaging we offer:

- folded blister

- folding (snap-on) blister

- multi-part blister

- inserts and other

Technical conditions

Preparation of the packaging production process - blisters consists in making dedicated matrices. Depending on the size of packaging and production, we make single and multiple matrices.

We present the basic technical and technological parameters for the production process:

- Foil

- materiał: PET, PVC, PS

- the thickness of the foil used depends on the size and weight of the product packed from 0.2mm to 1mm

- Forms

- multiple, made of polyurethane epoxy resins (durable and cheap)

- The maximum dimension of the form

- 950 x 650 mm

- Maximum dimensions of blisters:

- folded blister pack: max 530 x 360 mm

- folded blister: max 600 x 450 mm

- inserts and others: max as the size of the form

- max height for all types: 140 mm

- the number of sockets on the form depends on the dimensions of a single blister

- Punching:

- roller

The thickness of the foil used depends on the size and weight of the packaged product.

Data for valuation

In order to perform the valuation, the contractor must be provided with appropriate documentation to enable the correct calculation of all costs. Transfer of improper documentation, introduction of undocumented additional changes or technological operations may result in non-acceptance and re-valuation process.

In order to facilitate the preparation of relevant documentation and files by Principals, we provide some tips and information that should be used at the stage of preparing the project for the order.

To evaluate the assembly costs, please provide:

- Packaging design data:

- Files with dimensions of 2D or 3D packed items in CAD or pattern.

- Dimensions, thickness and material of the packaging.

- Are there special markings, embossed inscriptions on the packaging.

The customer will provide files enabling the design of the packaging, or packaging design

- Production volume, production series - production schedule, will receivew.

- Production volume, production series - production schedule, will receive...

- Method of packaging:

- Bulk packaging, boxes, bags, stickers.

- Delivery method, frequency of deliveryk.

Machinery

We have the following machines:

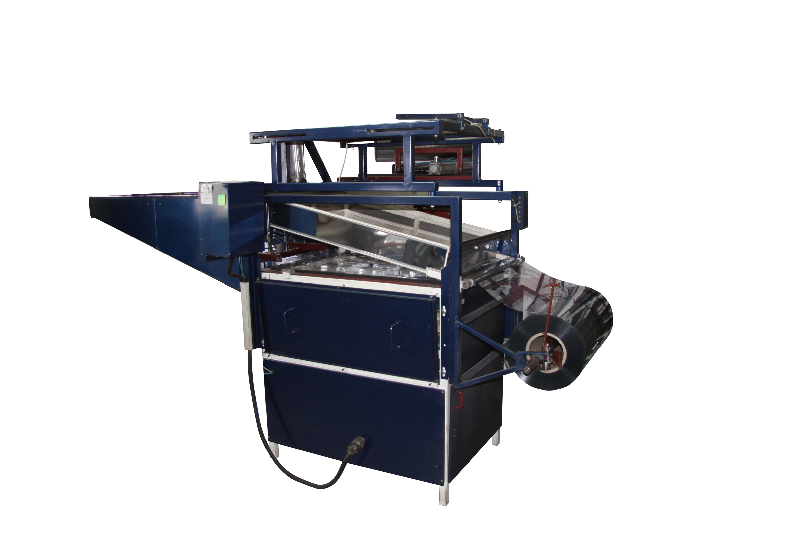

1. TERMOFORMIERKA próżniowa B-1F PEX

- effective forming surface: 650 mm x 950 mm;

- smooth format adjustment, interchangeable frames;

- table stroke: 300 mm;

- foil width: 700 mm;

- heating panel power -13 kW, ELSTEIN radiators;

- thermoregulators with a smooth adjustment range: 0 ÷ 600 ºC;

- control of FEST processor;

- formed material thickness up to 6 mm.

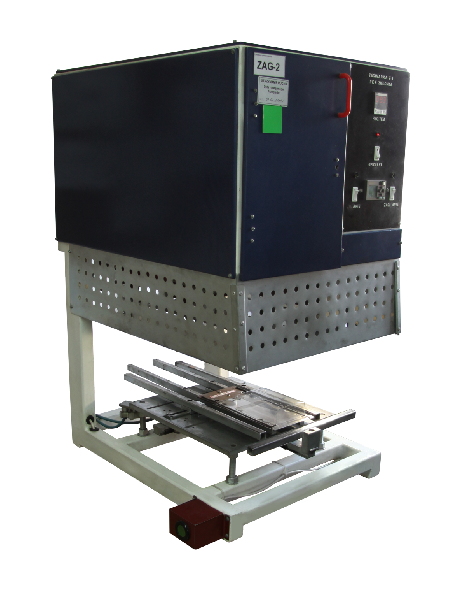

2. THERMAL BENDING MACHINE Z-3 PEX

It is designed to fold three BLISTER packaging edges simultaneously

Basic data:

- maximum format of the folded packaging: A-4/210 x 297 mm;

- minimum format of the folded packaging: 35 x 50 mm;

- thickness of the folded foil: max 0.8 mm;

- installed power: 2000W;

- the machine has stepless regulation of the dimension of the folded packaging;

- two replaceable tables for fixing the folded packaging.

3. ROLL PUNCHING MACHINESTAN-58

Universal device for cutting and creasing corrugated cardboard (including five-layer) and solid, foil (both flat and vacuum formed sheets), paper, leather, sponge and other similar materials.

contact

Jarosław Michalczak

Tel. +48 32 210 46 65 wew. 355

e-mail: jaroslaw.michalczak@zamel.pl

www.omix.pl