FINAL ASSEMBLY

Manual assembly

We offer comprehensive manual complementary assembly consisting in carrying out production activities by properly trained assembly staff. We have a set of assembly sockets located in separate rooms divided into electronic and mechanical assembly. We can perform the following operations at specialized positions:

- fixing electronic components and subassemblies in the housing components;

- screwing mechanical components with threaded connections;

- riveting, pressing with hand presses;

- hot and cold bonding;

- construction of complete devices from elements supplied or produced with us;

- making connections with wires, bundles, assembly of electrical apparatus;

- applying prints, markings, stickers.

Semi-automatic assembly

For serial production, we offer dedicated tools and instruments that partially automate selected production processes. We have a design office which, using advanced 3D software, is able to design high-class tools and mechanisms.

In our own workshop, we are able to make, modify and repair tools and mechanical components.

In our own workshop, we are able to make, modify and repair tools and mechanical components.

Automatic assembly

For the needs of large-scale production or requiring special process conditions, we design and manufacture automatic production lines or single automated robots. We use robots and components from the best suppliers in the field of robotics for configuration.

Currently, we use, among others fully robotic machine for mounting sockets and a robot supporting the collection of elements from the injection molding machine.

Currently, we use, among others fully robotic machine for mounting sockets and a robot supporting the collection of elements from the injection molding machine.

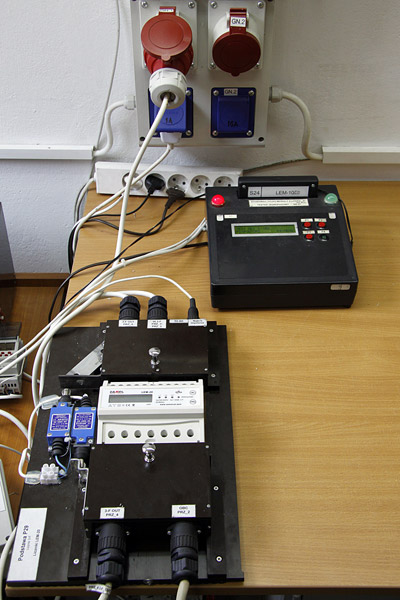

Testing

At the end of each production process, we perform tests that confirm or not - compliance of the product with the requirements.

Based on the provided product documentation, we can plan a number of tests and design and perform dedicated testers.

We test the given electrical and mechanical parameters. The result of each test is saved in the form of an electronic report and can be printed out on request.

Based on the provided product documentation, we can plan a number of tests and design and perform dedicated testers.

We test the given electrical and mechanical parameters. The result of each test is saved in the form of an electronic report and can be printed out on request.