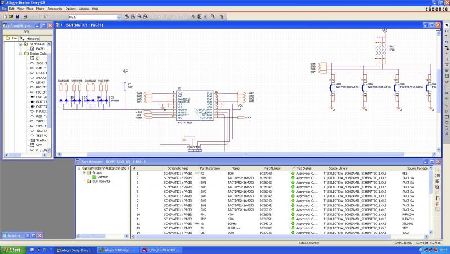

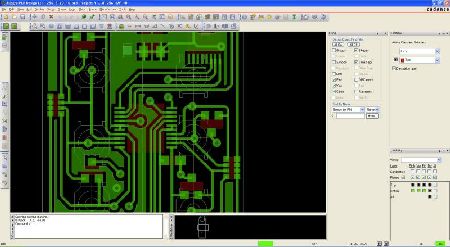

Electronics design

- Cadence Allegro;

- Altium Designer;

- CAM350 DownStream Technologies.

Customers we guarantee full confidentiality during and after design work. The rules of cooperation are governed by the contract concluded before starting cooperation.

We offer the following stages of order execution:

- detailed development of project assumptions,

- exact valuation,

- preparation of the scheme,

- PCB design,

- component assembly, PCB design,

- prototype assembly,

- circuit programming,

- commissioning and testing,

- assembly of the final prototype,

- preparation of production documentation,

- production preparation,

- selection of suppliers, purchase of elements,

- production on our own SMT and THT assembly line, details SMT/THT MOUNTING .

In addition, we offer dedicated software for digital circuits. When programming, we use the following platforms and languages:

- Languages: ANSI C, C ++, Assembler;

- Interfaces: USB, IrDA, RS-485/232, I2C, I2S, SPI;

- Network protocols: UDP, TCP, IPv4, IPv6, HTTP, SOAP, RPC;

- WEB: HTML, PHP, JavaScript, XML, CSS;

- Databases: SQL, MySQL, XML-based;

- Platforms: Windows, Linux, .NET, Java, LabView;

- Development environments: AVR Studio, MPLAB.

We invite you to take advantage of the comprehensive service of orders: design execution, technical preparation of production, purchase of components, sub-assemblies, printed circuits, SMT and THT assembly as well as mechanical assembly, testing of finished and semi-finished products, storage and full logistics service with proper packaging.

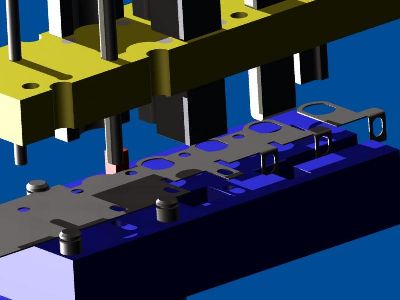

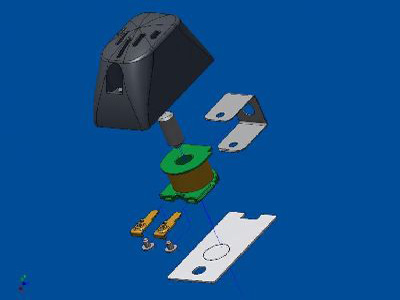

Mechanics design

We carry out projects and documentation in our design officemechanical devices. There are parts in the design areamachines, mechanical constructions, industrial casings, modifications andimprovement of existing structures. We prepare projects frombasics or based on client's concept sketches.We draw up executive drawings and develop product technology fromfull documentation.

In order to provide high quality services we have inour office of experienced constructors, we additionally pay backparticular attention to meeting the requirements of standards and assurance proceduresthe highest quality of services and products of our clients.

We use advanced CAD 2 / 3D design software:

- Autodesk INVENTOR 2011 SUITE,

- Autodesk INVENTOR 2011 SIMULATION,

- Auto CAD LT 2011.

As part of the project, we provide technical documentation in the CAD standard. Projects are performed in a parametric way, which allows for quick changes and modifications, as well as quick execution of subsequent versions of projects. We also make visualizations in terms of user instructions, technical documentation (DTR) and visualizations for the needs of advertising and catalog materials.

Scope of services:

- design of industrial designs,

- engineering design of product mechanics (3D),

- design of graphic elements,

- design of machine parts,

- design of sheet metal parts,

- design of industrial and industrial product housings,

- selection of plastic or metal optimal for a given application ,

- material identification of the supplied plastic and metal elements,

- cooperation with professional tool shops in the design and implementation of injection molds, blanking dies,

- design and implementation of technological equipment ,

- product prototypes and possible verification tests (3D stereolithography in cooperation)

- implementation of the project for serial production,

- production at our plant, details: MECHANICAL MOUNTING

As part of the simulation, we conduct analysis of non-linear, fast-changing problems for various material models and various types of loads.